There are a few things to keep in mind when recovering refrigerant into a non pressurized container. The most important thing is to make sure that the container is properly rated for the pressure and temperature of the refrigerant you are using. You also want to make sure that the container is clean and dry before adding any refrigerant.

If you are unsure about any of these things, it is always best to consult with a professional before proceeding.

When recovering refrigerant into a non pressurized container, it’s important to follow some basic safety precautions. First, make sure the container is properly rated for the pressure of the refrigerant you’re using. Second, always open the valve slowly to avoid creating a sudden pressure difference that could cause the container to rupture.

Finally, be sure to monitor the pressure in the container carefully and stop adding refrigerant when it reaches the maximum safe level.

Following these simple steps will help ensure that you can safely and effectively recover refrigerant into a non pressurized container.

Refrigerant recovery of refrigeration system

When Recovering Cfc Hcfc Or Hfc Refrigerant into a Non-Pressurized Container from a Household Refrigerator With an Inoperable Compressor?

If your refrigerator’s compressor is inoperable, you can still recover the CFC, HCFC, or HFC refrigerant from the unit. However, you will need to use a non-pressurized container to do so. Here’s a step-by-step guide on how to safely and effectively recover refrigerant from an inoperable fridge:

1. First, make sure that the refrigerator is unplugged and that all food has been removed from it.

2. Next, locate the access panel for the fridge’s evaporator coils. This is usually located near the bottom of the fridge.

3. Once you have located the access panel, remove it so that you can access the coils.

4. Using a clean rag or sponge, wipe down the coils to remove any dirt or debris that may be present.

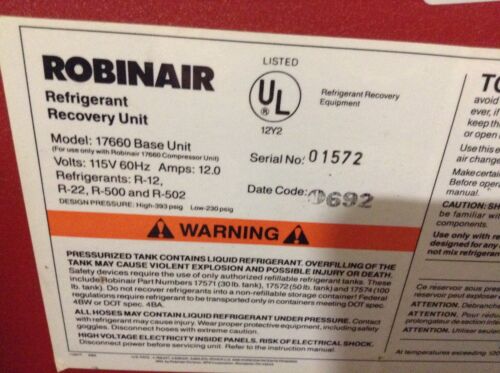

5. Now, using a recovery device (such as a Refrigerant Recovery Unit), connect it to one of the service valves on the evaporator coil tubing.

Make sure that all connections are tight and secure before proceeding.

6. Turn on your recovery device and allow it to run until all of the refrigerant has been recovered from the system (this could take 30 minutes or more). Once complete, turn off your recovery device and disconnect it from the tubing.

7 Finally, replace the access panel on your fridge and plug it back in (if desired).

When Recovering Refrigerant from Small Appliances You Must Recover?

When refrigerant is removed from a small appliance, it must be done in a way that doesn’t damage the appliance. The most common method is to use a vacuum pump. To remove the refrigerant, the appliance must be turned off and all of the power cords must be disconnected.

Once this is done, the vacuum pump can be attached to the appliance. The pump will remove the refrigerant from the appliance and store it in a container.

When Refrigerant Must Be Recovered from a System That Has an Inoperable Compressor?

Answer: When a system’s compressor is inoperable, the refrigerant must be recovered before any repairs can be made. This is because the compressor is what circulates the refrigerant throughout the system. Without it, the coolant will simply sit in one place and not do its job properly.

What are Recommended Safe Work Practices When Recovering Refrigerant?

When it comes to working with refrigerant, there are a few recommended safe work practices that you should always follow in order to protect yourself and others. First, always make sure that you’re wearing the proper personal protective equipment (PPE). This includes things like gloves, goggles, and a respirator.

Second, be sure to work in a well-ventilated area. Refrigerant can be harmful if inhaled, so it’s important to make sure that you’re not exposed to too much of it. Third, never mix different types of refrigerant together.

Doing so could create a dangerous chemical reaction. Finally, always properly dispose of any leftover refrigerant according to local regulations. By following these simple safety tips, you can help ensure a safe working environment for everyone involved.

Credit: www.govplanet.com

A Passive System-Dependent Recovery Process for Small Appliances

When a small appliance breaks, it can be a pain to have to go through the process of finding a replacement. With a passive system-dependent recovery process for small appliances, however, the process can be much easier. This type of recovery process relies on the fact that many appliances are now made with built-in sensors that can detect when they are no longer functioning properly.

These sensors send out a signal that is then used by the manufacturer to automatically send a replacement appliance to the customer. In some cases, the customer may even be able to keep using their old appliance until the new one arrives. This type of system-dependent recovery process can take away a lot of the hassle and stress associated with replacing small appliances.

If a Large Leak of Refrigerant Occurs Such As from a Filled Cylinder in an Enclosed Area

If a large leak of refrigerant occurs such as from a filled cylinder in an enclosed area, the following steps should be taken:

1. Immediately evacuate the area and ventilate if possible.

2. Do not re-enter the area until it has been determined that it is safe to do so.

3. If you come into contact with the leaked refrigerant, wash the affected area with soap and water as soon as possible. Seek medical attention if necessary.

4. Call your local gas company or emergency services to report the leak and have them shut off any gas lines in the vicinity if necessary.

When R-500 is Recovered from an Appliance It

When R-500 is Recovered from an Appliance It

R-500 (also known as HCFC-125) is a hydrochlorofluorocarbon that was used as a refrigerant in some appliances. When these appliances are disposed of, the refrigerant must be properly recovered and recycled.

There are two ways to recover R-500 from an appliance: self-service and full-service. With self-service, the owner of the appliance removes the refrigerant themselves and brings it to a recycling center. Full-service recovery involves a trained technician coming to the home or business to remove the refrigerant.

The Environmental Protection Agency (EPA) requires that all technicians who recover R-500 be certified by passing an EPA exam. Once recovered, the refrigerant must be taken to a facility that recycles it. This can be done through an exchange program, where new refrigerant is traded for used, or by buying recycled product from a supplier.

Before Beginning a Refrigerant Recovery Procedure, It is Always Necessary To;

Before beginning a refrigerant recovery procedure, always take the necessary precautions to protect yourself and your equipment. These include wearing gloves, goggles and a face mask, as well as ensuring that the area you are working in is well ventilated. In addition, make sure that the refrigerant you are using is compatible with your recovery system.

What Must Be Done to the Refrigerant That is Vented off the Top When Filling a Charging Cylinder?

If you are working with a refrigerant that needs to be vented off the top when filling a charging cylinder, there are a few things that need to be done in order to ensure safety. First, always read the manufacturer’s instructions carefully before starting any work. Second, make sure that the area around the charging cylinder is well-ventilated.

Third, wear gloves and eye protection while handling the refrigerant. Fourth, use only clean, dry charged cylinders. Fifth, open the valve slowly to release any pressure build-up before disconnecting the charging hose.

Finally, close the valve after disconnecting the hose and wait for all residual refrigerant to evaporate before recharging the system.

When Installing Any Type of Access Fitting

Installing any type of access fitting can be a tricky process, especially if you’re not familiar with the product or the installation process. Here are some tips to help you through the process:

-Before beginning the installation, make sure that you have all of the necessary tools and materials.

This includes the access fitting itself, as well as screws, anchors, and sealant (if needed).

-If possible, find a friend or family member who can help you with the installation. Having an extra set of hands will make things go much smoother.

-Carefully read through the instructions that come with your chosen access fitting. This will give you a good idea of what steps need to be taken in order to complete the installation correctly.

-If you’re not confident in your abilities to install the access fitting yourself, don’t hesitate to hire a professional.

They will be able to get the job done quickly and efficiently, ensuring that it’s done right the first time.

When Checking for Non-Condensables Inside a Recovery Cylinder

When checking for non-condensables inside a recovery cylinder, be sure to use the correct procedure and equipment. First, open the valve on the recovery cylinder and allow any pressure to escape. Next, remove the dust cap from the Schrader valve and use a clean dry cloth to wipe off any dirt or debris.

Once the dust cap is removed, use a non-condensing gas detector to check for any leaks in the system. If there are no leaks, close the valve on the recovery cylinder and replace the dust cap.

The System-Dependent (Passive Recovery Process)

System-Dependent (Passive Recovery Process):

The System-Dependent Passive Recovery Process is a process that is used to recover data from a failed system. This process requires the use of another system that is running the same operating system as the failed system.

The System-Dependent Passive Recovery Process can be used to recover data from a failed system by using an image of the failed system, or by using a backup of the failed system.

Conclusion

When refrigerant is being recovered into a non pressurized container, the process must be done correctly in order to avoid any damage to the equipment. There are three main steps that need to be followed: opening the valve slowly, allowing the refrigerant to flow into the container, and then closing the valve. After the valve is closed, it is important to check for any leaks before starting the recovery process again.